Vibrating Screen Mesh - Wear and Abrasion Resistance

Vibrating screen mesh is mainly used on vibrating screen machines for screening and sizing all kinds of sand, gravel, coal, stone, rock and other materials in mineral, metallurgy, quarry and other industries.

What types of vibrating screen can we supply?

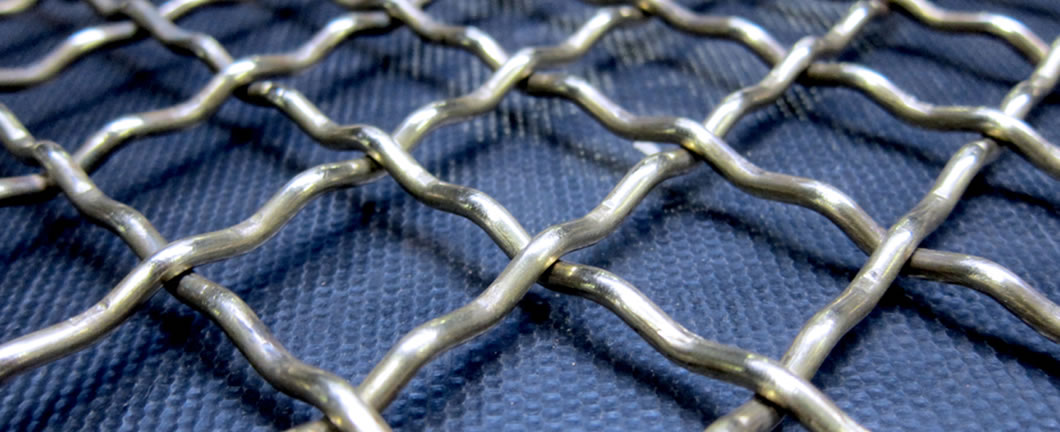

- Woven vibrating screen mesh. it is the most popular and widely used type of vibrating screen mesh. It contains high tensile spring steel vibrating screen mesh, manganese steel vibrating screen mesh and stainless steel vibrating screen mesh.

Woven vibrating screen mesh has different weaving method and various edge types.

Woven vibrating screen mesh has various weaving types. - Perforated vibrating screen mesh. It is made of high tensile strength metal sheet and then punched to the round hole, square hole and hexagonal hole.

- Square hole is the most frequency used type of the three. It offers the maximum open area for the screen.

- Round hole supplies the minimum open area. It can be used in the places where the sizing is strictly requirements.

- Hexagonal hole is the compromise of the round hole and square hole. It can be used in the places where the size is important but not strict.

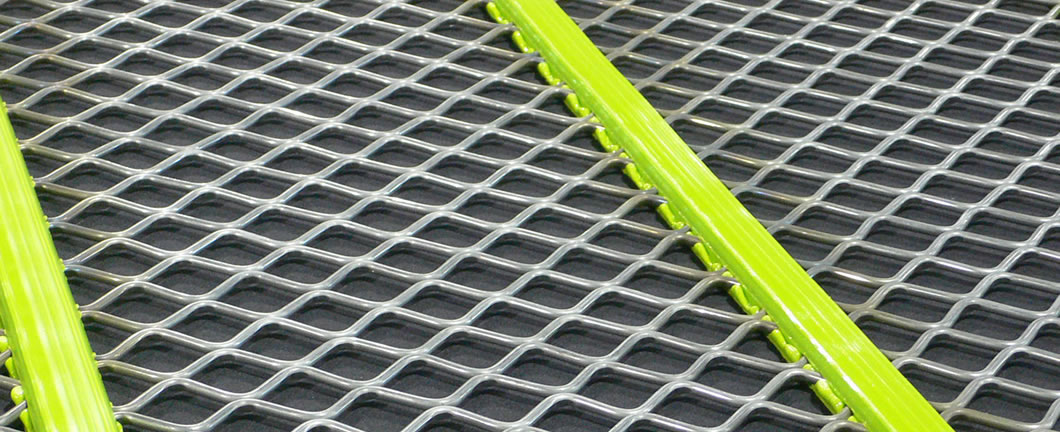

- Polyurethane vibrating screen mesh. It is a special structure, which contains metal steel wire inside and polyurethane surface outside. The polyurethane has great wear resistance performance, it can supply the extra wear life for the screen and save the replacement time and improve the screening efficiency.

- Piano wire screen. Piano wire screen is a simple structure, which is formed by longitudinal wires, which are fixed into a metal or plastic sliding bar to keep wires in place and maintain the opening size. There is no other cross wire on the screen, so it supplies more open areas for the screen. It is widely used for screening the wet, sticky and other materials. The wire diameter and spacing between the air can be customed.

- Self cleaning screen mesh. Self cleaning screen mesh has three types: W mesh, D mesh and H mesh. They all have the ability of self cleaning. It can offer effective solutions to difficult sizing and reduce the blinding and plugging.

- Trommel screen mesh. Trommel screen mesh is the variation of the vibrating screen mesh. It is particularly effective on lighter, wetter materials, like mulch, topsoil and compost for more safety and high efficiency.

Vibrating screen mesh has various applications.

Features of the vibrating screen mesh

- High tensile strength and toughness. All the screen is made by the high tensile steel, it can supply the high tensile strength and toughness.

- Wear and abrasion resistance. All the materials are wear and abrasion resistance.

- High temperature resistance - spring steel vibrating screen mesh and manganese vibrating screen mesh.

- Long service life. The high quality raw material and strict production can improve the service life of the screen.

- Customed. All types of vibrating screens can be customed according to the customers' requirements.

- Reduce the blinding and plugging - Piano wire screen and self cleaning screen mesh.

- Safe and high efficiency. Especially for the trommel screen mesh.

Various application of the vibrating screen mesh

- Most of the vibrating screen mesh can be installed on the vibrating screen machines, quarry screen machines and crusher screen machines to separate lighter and wetter materials in the chemical, coal, construction, plastic, metallurgy, mineral-selecting, agriculture, etc.

- Piano wire screen is widely used for screening the wet, sticky, damp, dry abrasive and other materials.

- Trommel screen mesh is used for separating the lighter and wetter materials.

- Self cleaning screen mesh is used for sizing the sand, gravel and other materials which may cause the blinding and plugging.

HOT SALE PRODUCTS

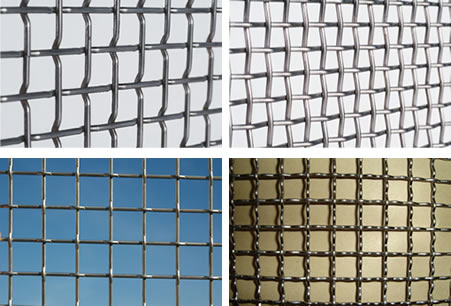

Woven vibrating screen mesh with different materials, woven types, edge and hooks is widely used in the vibrating screen, quarry and crusher screen.

Spring steel screen mesh with high and medium carbon steel materials is wear and abrasion resistant to be used in vibrating, crusher and mining screens.

Manganese steel vibrating screen mesh has high tensile, rust and corrosion resistance to separate all kinds of gravel, rock and other materials.